My first love was engineering, not writing.In October 1957, Americans were stunned by Soviet success in putting the first satellite into orbit and responded by accelerated high school education in mathematics, science and engineering. Winner of a state "Science Fair" and already a founding member of the preteen Orange County (Florida) Rocket Society when Sputnik went up, in due course I won a high school scholarship to MIT. I looked forward to being a part of the U.S. space program. I dreamed of working for NASA and contributing to the inevitable attempt to put astronauts on the moon. In the early 1960s, I was sure that earthlings would land on Mars, and possibly even head out of our solar system, in my lifetime.

Between 1962 and 1966, various physical and emotional traumas inflicted on me, and also inflicted on many other victims, resulted in partial amnesia, including the loss of all the mathematics I had learned in accelerated courses. An advanced engineering degree was out of the question. I turned to writing to make a living, to make a contribution to the world and to express myself. These traumatic events also forced me to re-evaluate many of my previous patriotic high-tech and semi-militaristic values. I then decided to reside in Canada, or in Europe, because of these then-recent and unpleasant experiences associated with supposedly defending my native United States. I felt that I'd been duped into defending American hypocrisy. Other countries are just as self-serving, but few are so hypocritical about it. That, at least, is some relief.

Always fond of history as a second love, I began to hatch some heretical and disreputable thoughts about the true profile of Western history and “progress”. I began to see history and technology from a Third World perspective. And, perhaps inevitably, I developed immense sympathy and sorrow because of the human cost of Western history and its progress on non-Western peoples. The suspicion also entered my mind that Western history and our brand of “progress” could not be sustained forever by the world we share. We would someday have to mend our ways -- unless we simply chose to impose our values off earth by going into space once we'd dirtied our earthly nest beyond psychological or physical redemption.

Between 1979 and 1983, forced to indulge in only simple and basic “engineering”, I formed a company to design and build low/appropriate technology products intended for impoverished Third World populations. In association with the Canadian International Development Agency regarding some projects, CanTraid built inexpensive village fishing boats, wind-powered and steam-powered motors to propel fishing boats, produce electricity and pump water – and a few other things. I thought that, sooner or later, even the proudly high-tech Western world would be forced to adopt a Third World or “survivalist” view of viable human life. At least, I hoped so.

I waited a long time for this to begin happening. Some of these products and perspectives are related in my in-progress “Hot Air and Ancient Wonders” book.

Only very recently, in Year 2000, have some individuals and communities contacted me about some designs that I originally made for use in Asia, West Africa and the Caribbean over twenty years ago.

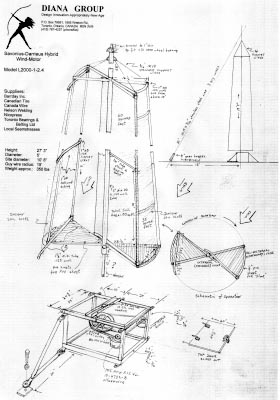

My homepage will display some of these things, as they can be added along with books, articles and screenwriting. None of these things are patented, and interested parties are welcome to adapt the concepts. For those who feel more secure following plans, however, the wind-motor schematic plan and specs shown is available for $100 USD.

Because of some very recent interest in some of these concepts on the part of environmentalists and survivalists, I've formed a small company to market both a modest number of manufactured products within a practical radius of Toronto and to offer plans for people further afield. This little company is the DIANA GROUP – an acronym for “Design Innovation Appropriately New Age”.

Wind-Motor

This hybrid Savonius-Darrieus windmill is a vertical axis omni-directional self-starter. It starts in Savonius mode. At about 60 rpm it naturally makes its transition to Darrieus mode due to centrifugal force acting on the internal (movable) vanes. But I made a simple gadget to delay this transition if continued high-torque is desirable for some reason (i.e. water pumping, direct drive for tool accessories and marine propulsion). This windmill was originally designed in 1979, and 20 units were supplied to Sri Lanka (1982) for testing as propulsion on their north coast fishing catamarans (the catamarans themselves were made by Gifford Technology of Southampton, England).The final marine drive was mechanical. That's why I called this thing a "wind-motor", and the name stuck. Marine drive was via an interesting vertical axis impeller “jet” drive – like a low-speed high-volume “Cal Jet” for the Third World (the casing was a modified upscale stainless steel cooking pot!).

There's less thrust loss (no prop tip loss) with an enclosed impeller. Also, both reverse and side-thrust were obtained simply by rotating the pot. Neat, no transmission. Why don't all boats use impellers? No danger for swimmers or manatees. No entanglement of ropes. No problem in sand or when bumping rocks. Simpler and more efficient for inboards and outboards, especially on canals where bank erosion because of lateral propeller-tip thrust is a concern. Anyway...

This "wind-motor with impeller drive", originally designed for Sri Lankan catamarans, inspired me to make a 24-foot barge for doing Grail-related research (1987-1992) along U.S. and Canadian waterways. This unlikely vessel also had "conventional" sail power (Polynesian crab-claw lateens) and provision for a gasoline engine to drive the impeller with an automotive belt, but I slung a conventional outboard over the stern to make Canadian DOT (Department of Transport) boat inspection officers happy. See "Grail Knights of North America", page 333.

This barge proved useful, and the "wind-motor with (direct drive) impeller" concept was really effective, even on this ungainly vessel. It evolved into rather detailed and elegant plans for a larger, folding (!) 2-4 person cruising, work, research, filming or survivalist boat that would primarily use "wind-motor with impeller" (electric) drive. It also incorporates conventional sails, gasoline power using a standard portable generator (also handy ashore) and even provision for auxilliary steam power.

Folding to half its floating length, this boat would be easier to trailer than it would otherwise be – and its (floating) trailer can come aboard the front deck, through a landing-craft type door-ramp, as an on-board ATV and fully amphibious vehicle. As for this trailer-vehicle, I've powered one with a 500cc motorcycle engine (dubbed "La Tarasque" after a mythical French monster because of the fearsome and noisy system of forward/reverse external chain drive), but never got around to installing my 3-moving part all-purpose steam engine. An on-board trailer-vehicle not only makes better and ongoing use of the trailer, but is handy for exploring if it has sufficient power. It is even handier for doing shopping, if it can make normal road speed. I had always planned to make a smallish version of this highly integrated "wind-motor/boat/trailer" design for doing Grail-related research along smaller European waterways, especially the Canal du Midi and Narbonnais etangs. I still hope to do this.

Aside from survivalism, this boat is intended for scientific research and/or filming in remote locations. I designed two units (different sizes) for Production Services, a Toronto-based film equipment rental company, but to my knowledge they were never made. I'm presently in touch with several documentary film production companies, a few private researchers, the National Geographic Society and a few Third World countries about this vessel. I will put this "wind-motor with impeller on a folding boat" idea on the Website as soon as possible. But it is really another product -- even if it does incorporate the wind-motor...

Anyway...those original Sri Lankan wind-motors worked well in the Monsoon-strength winds (especially in the flukey winds of transition time), because the wind-motor responds almost instantly to any change in wind direction. Also, they are not fussy about being absolutely vertical. They will work in modest waves. But eventually political pressure on the Sri Lankan government applied by Western government-supported aid agencies dictated the purchase of much more expensive Western-manufactured low-power outboards for fishermen who couldn't afford them or the gasoline. Or repair them. Yep, the Aid Biz as usual.

Anyway…later, some land-based units intended for both water-pumping and electricity-generation were used in the Caribbean. I could not find any large company to manufacture them in mass-production quantities because the wind-motors were too simple and too inexpensive. There was insufficient profit-per-unit, or so I was told, especially given a Third World primary market. On the other hand, wind-motors were not complex enough or sophisticated-looking enough to gain a North American market -- and besides, back in the '80s, North Americans were still mostly power crazy. This must have been true because no one (to my knowledge) "stole" the idea and put these wind-motors into production.

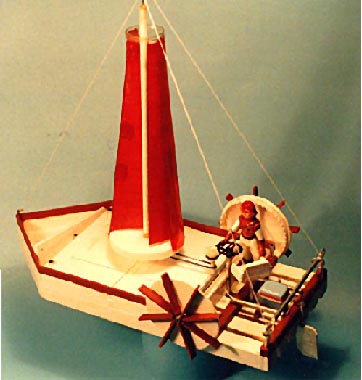

In 1983, a small Ottawa-based Canadian company asked me to revert to the marine thing and design a wind-motor for a recreational pontoon-platform type of recreational boat. The mill produced electricity to charge batteries that fed a small motor that turned either an updated impeller or “cute” paddle-wheels. The product was for cottage Seniors and/or small lakes where residents had legislated against noise and gasoline-slick pollution caused by motorboats. There are an increasing number of such lakeside communities in Canada – I don't know about the States. This worked for stately cruising in any sort of fickle wind caused by Canadian Shield geography, and the battery would get it back to the dock if the wind failed (in most cases! An extra charged or chargeable battery might be needed.).

I also designed and made prototypes of smaller units designed to clamp across canoes and/or fishing skiffs (with integral outrigger floats).

The small Canadian company failed, unfortunately, and I have no photos of their prototype. But here's a picture of a model paddle-wheeler on a Heyerdahl-esq “neo-raft” that I did for a friend. He never built it.

I've made about twenty different experimental models of wind-motors in various materials and with two, three or four aerofoil-vanes, ranging from four feet high to over twenty feet high. I've gotten over 325 rpm (in a 25 mph wind) with some of them.In February 2000, an environmental/survivalist group in Ontario approached me to make a production prototype against the possibility of 20-100 local and Internet orders if the thing worked as I have described. I agreed to make a production prototype/demonstrator to be in service by August 26, 2000.

This is a simple, robust basic 2-vane (and 2-alternator) model designed to produce about 2.4 KW in 25 mph wind. It uses off-the-shelf automotive bearings, alternators, etc. It is about as “Third World” as I could make it for North Americans. This crude drawing doesn't show all the crucial details (be warned!) but is good enough to get the fundamental idea. I'll put a photo of the prototype into the homepage when it's up and running.

As a update to this story, the weather patterns of Year 2000 precluded the erection of the full size wind-motor for August 26. Forecasts either called for too little wind or too much (with thunderstorms). The forecasts proved accurate. Therefore, instead of the full size thing, I hastily refurbished an existing large scale model (over five feet high) that could be demonstrated inside without recourse to outside weather.

This was duly, and very successfully, demonstrated to various groups and individuals from August 26 onwards (newspaper article September 16, 2000). It showed the operating principle and the construction well enough to generate several orders. The idea is that when this year's delayed weather patterns finally shift into "autumn mode", delivery of full size units can begin.

This rough plan and schematic, $100 USD.

The North American version calls for either welded steel or aluminum tubing to form the vertical sail frames, and calls for dacron cloth for the vanes. It uses two belt-driven 105-amp automotive alternators turned at a high ratio by an 18-inch diameter cast iron pulley on the main shaft. Be warned! There's an inter-drive (not shown) to achieve sufficient alternator rpm.This is virtually a copy of a design made on the Colombian island group of San Andres between 1980-83. There, however, we used large lashed-together bamboos for the vertical frame members -- and there's nothing better for this than bamboo (not even aluminum)! Local cotton was used for the vanes, and the vanes were sewn by village women. We used various junked auto generators. The guy wires were ropes set up with lanyards and dead eyes. The flywheels/pulleys were junked automotive wheel rims. These primitive wind-motors worked well in the Trade Winds when mounted on the roof of houses and they charged automotive batteries for 12 VDC interior lighting and for some appliances. Over 60 San Andres wind-motors were produced locally over three years. We later supplied some remanufactured alternators from Canada since these were the most difficult components to find in working order on San Andres.

As far as I'm concerned, the wind-motor supplies 12VDC at its outlet. The transmission of power and the battery storage system are the customer's responsibility.

This windmill is not the most efficient design in the world, and cannot match the performance of sophisticated American, Aussie, Swiss, British and Kenyan horizonal-axis prop-mills mounted on high steel towers. On the other hand, these highly efficient mills are priced at around $35,000 (Can.) each, while wind-motors are currently priced at about $4000 each if the DIANA GROUP makes them. But with care, proper equipment, welding and mechanical skill and new or remanufactured auto parts, a wind-motor could be home-built to plans for about $1500, discounting labour. Less -- if you scrounge parts and material and do all the work yourself.

This is a thoroughly "Third World" concept. It may not, therefore, appeal to high-tech alternative energy buffs who, naturally in the Western World, consider themselves to be the "experts" in this new financial growth industry. Remember, these new-fangled consultants emphasize engineering and complexity to clients who may know little or nothing about basic mechanics or electricity. They also usually charge a fee proportional to the customer's investment. No wonder they advocate the utmost in efficiency! It pays...them. Producing basic electricity from basic wind is really rather simple. There's always been money in emphasizing complexity and then in selling the "expertise" needed to overcome complexity.

Anyway...what you lose in efficiency with this basic design, you gain in first cost, ease of ongoing maintenance and home repair and (for a Canadian or northern U.S. climate) the advantage that all the energy-producing goodies are weather-protected at ground level for easy access.

If you want or need more electrical energy, well, put up more wind-motors. An array of several small and simple units has an inherent human advantage over just one large and sophisticated installation. If one unit breaks down, gets damaged or freezes up, not all of your electrical generation capability is lost. And, with good "cordless" rechargeable electrical tools, you can even use your remaining electrical capacity to repair more quickly a disabled wind-motor.

Also, being light in weight, any given wind-motor can be erected or dismantled by 2-3 adults (mechanical "come alongs" would help) at a pinch without any reliance upon mobile cranes, etc. The base of the wind-motor has been designed to facilitate this erection-and-dismantling process. Wind-motors have a motorcycle-type brake. They can be stopped very quickly, and then "reefed" at the onset of a Sri Lankan gale or an exceptional North American storm.

In conclusion, for those who are interested, my San Andres bamboo experience inspired me to try to make a "temperate zone" and "ancient replica" version of this wind-motor. The sail frames were made of wooden poles (spruce) lashed together with rawhide thongs. I wanted to use flax linen (but found it expensive), and settled for raw unbleached cotton sail cloth. My "bearings" (top and bottom) were round-ended bronze pins operating in shallow-cone brass plates sunk into a tree trunk segment. Guy wires were just cotton rope (woven rawhide would do) tightened with lanyards and dead-eyes, like on San Andres. This is just sailing ship technology as shown on Ancient Egyptian and Assyrian stone reliefs of "Heyerdahl-like" reed boats. However, I'd long suspected that northwestern Europeans knew at least as much about ship rigging as Ancient Egyptians or Sumerians/Assyrians.

I used this contraption amidships on one of our standard curraghs. A wooden-bladed impeller operated within a sewn canvas well (skin or leather in a traditional curragh) just beside the keel which supported the tree trunk segment bronze pin bearing.. This primitive "wind-motor and impeller"-driven curragh was very difficult to get right. We fiddled with the relative size of the impeller and wind-motor for weeks (in our spare time). But it worked at last, and worked well, though the rig needed constant adjustment and frequent greasing with animal fat. The important thing, however, was that the curragh would sail at 3-4 knots no matter what the direction of the wind. Eventually, we loaded a scale-size "bluestone" (about a ton) into our 32-foot standard CanTraid curragh and sailed it 65 miles in the tricky currents and winds of the Bay of Fundy.

I'm not saying that wind-motor powered curraghs were used in Megalithic times in Northwest Europe. Conventional single square-sail curraghs would have served nicely to move bluestones to Stonehenge (for example). But there's nothing in the wind-motor concept or construction that is inherently beyond Megalithic-Neolithic intellects or technology. That being the case, we cannot discount smart windward sailing ability circa 4000 BC or before -- and this puts a possibly very different slant on the general flow of civilization. From the "Middle East"...or to the Middle East from Northwest Europe?

Eventually, I took this "ancient wind-motor" ashore and, with a little thought, made some "bits" for various uses and could also take power off the central shaft by a leather belt. I mention this because in my in-progress "Hot Air and Ancient Wonders" book I suggest that stone-cutting, stone-drilling, and stone-polishing could have been done by wind-motors working night and day in "hot air" (windy) regions. Such devices could help account for ancient wonders made by societies with limited populations (according to their known agricultural production).

For example, the curved-edge "Inca" stone blocks almost must have been made by a pair of wind-motors polishing back and forth with a leather (guanaco hide on cotton) band applying pressure to the face of a stone block. The rounded edges would just be an inevitable consequence of applying enough polishing pressure with a flexible band.

I've covered this in my upcoming and in-progress book, "Hot Air and Ancient Wonders".

|

|

click here for more... | back to previous |

|

Other related links |